What operations can you perform on PET felt?

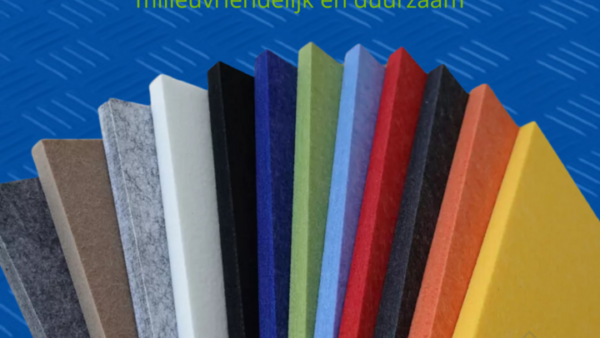

PET felt, made from recycled polyester, is a versatile material widely used in interior design, furniture manufacturing, and acoustic applications. Thanks to PET felt's robustness, durability and versatility, there are numerous processing options that designers and manufacturers can exploit to meet diverse project requirements. In this blog, we discuss the most common machining operations you can apply to PET felt.

1. Cutting and laser cutting

Cutting PET felt can be done manually or by machine, depending on the desired precision and complexity of the design. Laser cutting is a popular method for detailed designs, as the laser makes precise, sharp cuts while sealing the edges of the felt. This prevents the material from fraying and ensures a neat finish.

Applications: Laser cutting is often used to create patterns in acoustic panels, wall decorations or custom designs.

2. Milling

Milling is a technique in which a rotary cutting tool is used to remove material from the surface. In PET felt, milling is mainly used to create grooves, slots or to insert texture. Milling offers the possibility of creating three-dimensional structures in the material, making it ideal for architectural applications and interior design.

Applications: Acoustic panels with profiled surfaces, decorative wall coverings and panel structures.

3. Heat forming and thermoforming

PET felt has thermoplastic properties, meaning it is malleable when heated. Thermoforming makes it possible to bend, stamp or deform PET felt into complex, three-dimensional shapes. After cooling, the material retains its new shape. This technique is useful for creating ergonomic structures and complex design pieces.

Applications: Moulded panels for chairs, acoustic baffles and three-dimensional works of art.

4. Perforate

Perforating is a technique in which small holes or patterns are made in the material. For PET felt, this technique is often used for decorative purposes or to improve acoustic properties. Perforations can be done manually, but are usually machine-made to ensure a precise and consistent finish.

Applications: Acoustic panels and wall coverings with an aesthetic twist, air- and sound-permeable materials.

5. Printing and colour applications

PET felt can be printed with various ink types to apply colours, patterns or logos. Depending on the method and ink type, the material can be fully or partially printed. Sublimation printing is a popular technique for PET felt, as it provides durable, vibrant colours that penetrate deep into the material and do not fade quickly.

Applications: Customised projects such as wall panels with logos, art installations, and decorative accents in interiors.

6. Bonding and laminating

PET felt can be laminated or bonded to other materials to provide additional functionality. Lamination, for example, allows PET felt to be combined with hard panels or soft foam layers, increasing structural integrity or comfort. PET felt can also be coated with a self-adhesive layer, making it easy to attach to surfaces.

Applications: Acoustic panels with laminated structures, decorative wall coverings, and insulation panels.

Conclusion

The versatile processing capabilities of PET felt offer countless options for designers and manufacturers. Whether you want to cut simple shapes, laser cut complex patterns, or create three-dimensional shapes, PET felt is a material with endless possibilities. By choosing the right processing techniques, you can make the most of this durable material and use it in a wide range of applications.