Description

Grass paving made of plastic: fast and economical paving

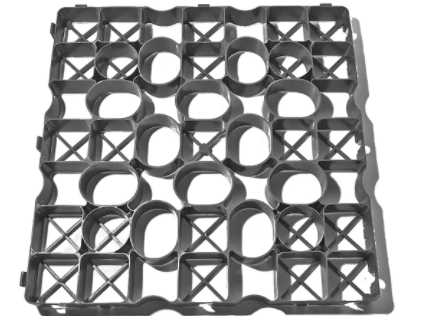

In combination with fleece, plastic grass slabs can be used to keep soil, gravel and grass in place and prevent mixing with the subbase. When plastic grass slabs are used as a grass application, it prevents ruts from being driven into the grass when traffic load is applied. Besides its stabilising property, the square plastic grass tile ensures that water is transferred to the underlying layer.

The applications of plastic grass tiles

Grass tiles made of plastic are used for a variety of purposes. For example, in the construction of:

- Parking spaces

- Outdoor events

- Verge paving

- Road widening

- Emergency jobs

- Paths and driveways

- Step mills

- Paddocks

Ecologically sound paving

As the water is drained to the underlying layer, the grass slabs thus prevent environmental problems. By using our plastic grass slabs, you create an environmentally-friendly and water-permeable paving. This keeps lawns and lawn areas even and stable. Moreover, the plastic grass blocks can be used for verge surfacing, reinforcing embankments and preventing erosion on dikes and embankments.

The technical properties of plastic grass grids

By using these plastic grass blocks, the grass or gravel will stay neatly in place, even when driven over. Check out the technical features of the tiles:

| Specifications | |

| Dimensions | 50 cm x 50 cm x 4 cm |

| Size of holes | 6.6×6.6 cm and 9.5×6.6 cm |

| Weight | 0.91 kg per plate |

| Colour | Black |

| Compressive strength | Filled 400 tonnes per m² |

| Frost and UV resistant | At temperatures of -30 to +50 degrees Celsius |

| Use | For e.g. gravel, grit and grass |

How do I install the plastic grass slabs?

The plastic grass blocks are easy to install thanks to the unique interlocking coupling system and thanks to the fact that the sheets are lightweight. One person can move around 100 m² per hour thanks to this system. This is partly because the grass slabs are very light. The slabs can be locked together via the connecting hooks. You then fill the synthetic grass tiles with soil, grass, gravel or grit. This makes it easy to install the tiles yourself.

If the surface of the plastic grass tile will be heavily loaded by cars and trucks, for example, we recommend laying a good solid foundation first. We recommend keeping about 2 to 5 cm free around the edge due to some thermal expansion. If necessary, it is also possible to lay an anti-root fabric under the slabs. This reduces weed growth.

Laying instructions at new paddocks

- Ensure levelled dry soil

- Lay down an anti-root cloth on the ground where you want to make the paddock

- Next, apply the underlayment. This should be made of 10-15 cm of well-drained material, e.g. crushed rubble 8-32 mm or gravel and make it flat

- Then level the entire surface with a layer of gravel or crushed rubble, not too coarse: about 2-5 mm. This layer is for levelling and only requires a thickness of about 2-3 cm

- Then lay the paddock slabs, possibly with an anti-root cloth underneath

- Then only lay the top layer of washed sand (grain size 0-2 mm), also called M3C sand. This layer should be at least 5-6 cm thick above the slabs, and should always cover the slabs

If you want to build a riding arena, you can also proceed differently. The bottom layer and top layer should be slightly thicker, i.e. 20-25 cm, and the top layer should be 8-10 cm thick.

The service of Plastic Forte

Why order grass tiles made of plastic from Plastic Forte? We list the advantages:

- Fast delivery time

- Pay safely

- Personalised service

- Wide online range, including garden materials as sedum cassette and gravel slabs

- Expert advice

Order synthetic turf tiles in our webshop

Interested in plastic grass tiles from Plastic Forte? Then order these tiles directly on our website or request a tailor-made offer to. First request more information about a plastic grass tile via the contact form is, of course, also an option. Furthermore, we are available by phone and e-mail for questions or comments. You may call us at +31 (0) 622 340 847 or send an e-mail to info@kunststofforte.nl. We will be happy to tell you more about the possibilities!