Description

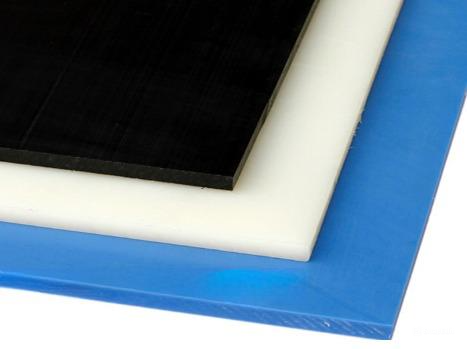

PE300 plate EXTRUDED

HDPE is also known as polyethylene or PE-HD. HDPE sheets in black are plastic sheets often used in several sectors within industry, including equipment construction, chemical industry, energy sector and precision engineering industry. This plastic sheet material is widely used in these sectors because the material has a good price-quality ratio. The sheets are made of impact-resistant plastic and absorb little or no moisture. Polyethylene is not the most widely used plastic in industry for nothing.

Why buy an HDPE sheet? The advantages of HDPE in a row:

- High impact resistance at low temperatures;

- Lower firmness and stiffness than PP-H;

- Very high chemical resistance;

- Available in various colours, including black;

- Maximum temperature in continuous operation approx. +80 °C, when the moulded part is not subjected to significant mechanical stress;

- Very low water absorption and physiologically safe;

- Good electrical insulating properties;

- Simple handling options.

Application of HDPE plastic sheets

You can HDPE sheets use for various applications. These include use in fish farms, tank construction, equipment construction, food industry, beverage industry, transport sector, orthopaedic applications and installation and equipment construction. Polythene is very widely used in the food industry because nothing sticks to the material and it is tasteless and odourless.

Especially HMPE plate P500 is widely used as cutting plates for the meat and fish industry. The plastic is also highly resistant to chemicals. This material is also very suitable for building extraction systems for embankments, in loading bins, chutes, containers, chemical equipment, playground equipment, cutting boards, slide rails and soundproof walls. However, HDPE plastic sheet material can be used for many more applications.

Made up of carbon and hydrogen molecules

A characteristic feature of HDPE is that the sheet material is still evolving, making it even better and more versatile. The fifth and newest generation is PE100-RC. HDPE or PE-HD is the abbreviation for high density polyethylene and is produced at low pressure using a catalyst. This catalyst binds ethylene molecules into very long molecular chains. Two molecular types are then linked together, the carbon and hydrogen molecules to be precise. The HDPE sheet belongs to the semi-crystalline plastics.

Processing of polyethylene

Gluing HDPE sheets is impossible because polyethylene is very greasy. HDPE P250 can be welded very well, whereas HMPE P500 and P1000 are again difficult to weld. If you want to attach this type of sheet, we recommend you do so via a mechanical connection, for example using screws. Please note the relatively large expansion of PE, as the expansion of PE amounts to mm per °C per metre length. Example: a 2000 mm x 1000 mm board mounted at 15 degrees will shrink about 6 mm (!) over its 2000 mm length at 0 degrees.

You can process an HDPE sheet in the following ways:

- Welding

- Adhesives

- Machining

- Water jet cutting

- Laser beam cutting

- Warm bending

- Cold brew

- Thermal forming

HDPE sheet to size

Looking for a customised HDPE sheet? The black HDPE sheets we supply can be ordered to size. You can choose a length of 200 or 300 mm, a width of 1000 or 1500 mm and a thickness of 2 to 20 mm. Do you need an HDPE sheet with a thickness of 10 mm, for example? You can order these entirely made-to-measure in the web shop.

Note any damage

As HDPE is made of a relatively soft type of plastic and is supplied without protective film, the sheets may be delivered slightly damaged. The material can also be easily damaged during use. We therefore recommend not using the material for presentation purposes. If you do want a high-quality finish of the PE sheet wishes, you should better use another type of plastic such as acrylic or plexiglass.

Order a PE plate black in the web shop

View the possibilities on our website, select the desired thickness, length and width of the PE sheet black and order a custom-made HDPE sheet in the web shop. When you place an order with us, you benefit from a fast delivery time, safe payment environment and personal service. Do you have a question about this product, or do you need expert help in choosing the right sheet material? Feel free to contact us for more information. For more information, please visit the contact form fill in, or call +31 (0) 622 340 847. We will be happy to tell you more about the possibilities.