Beschrijving

Wat is HDPE folie zwart?

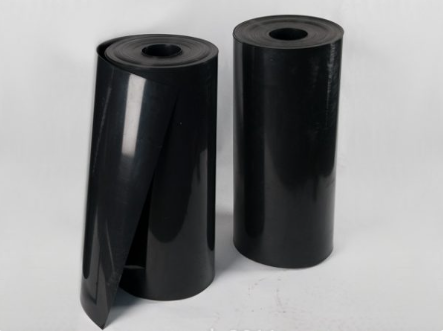

HDPE folie zwart is een sterke en duurzame kunststof folie die wordt gemaakt van High Density Polyethylene. Deze zwarte HDPE folie staat bekend om de hoge dichtheid, waterdichtheid en het kenmerkende knisperende karakter. Doordat HDPE wordt geproduceerd via een lagedrukproces ontstaat een zeer lineaire molecuulstructuur, waardoor HDPE folie zwart extra sterk en slijtvast is. Dit maakt het materiaal breed inzetbaar in de bouw, infrastructuur, landbouw en vijverbouw.

HDPE folie is verkrijgbaar in 1 mm en 2 mm dikte, in rollen van 25 tot 100 meter, met breedtes van 60 cm, 70 cm, 100 cm en 150 cm. Deze sterke folie is geschikt voor vochtwering, bouwprojecten en industriële toepassingen.

Toepassingen van HDPE folie

Deze stevige polyethyleenfolie wordt veel gebruikt als wortelwering, bouwfolie en beschermlaag. Denk aan toepassingen zoals:

- Bescherming van wegen, trottoirs en infrastructuur

- Drainage- en rioleringssystemen

- Kabeltracés en leidingen

- Wortelschermen rondom bomen

HDPE folie is daarnaast populair in landbouw, tuinbouw en vijverbouw. Door de waterdichtheid is het geschikt als vijverfolie, als barrière tegen vocht en als afdekfolie voor bodem en gewassen.

Landbouw en tuinbouw

In de agrarische sector wordt HDPE folie gebruikt om grond te beschermen en onkruidgroei te beperken. Bekijk ook onze folie voor landbouw en tuinbouw.

Vijvers en waterbassins

Dankzij de hoge dichtheid is deze folie bruikbaar in vijverconstructies, waterreservoirs en bassins.

Bouw en renovatie

Als dampremmende laag wordt HDPE veel toegepast in de bouwsector. Het voorkomt dat vocht in constructies dringt.

Eigenschappen van HDPE folie

- Bestand tegen chemicaliën en weersinvloeden

- Volledig waterdicht en niet-hygroscopisch

- Uitstekend bewerkbaar, zelfs geschikt voor smeltlassen

- Veel sterker dan LDPE-folie

- UV-resistent en geschikt voor langdurig buitengebruik

- Geurloos en veilig voor voedseltoepassingen

- Recyclebaar en energiezuinig in productie (RVO – duurzaamheid)

Doordat het materiaal licht is, maar sterk en duurzaam, heeft het een lagere CO2-voetafdruk dan veel alternatieve verpakkingsmaterialen.

Verschil tussen LDPE en HDPE

LDPE (Low Density Polyethylene) en HDPE zijn beide typen polyetheen, maar verschillen in structuur en eigenschappen.

LDPE

- Meer vertakte molecuulstructuur

- Flexibel en zachter

- Gebruikt voor plastic zakken, folie en verpakkingen

HDPE

- Lineaire structuur met weinig zijtakken

- Sterk, stijf en zeer slijtvast

- Deze folie is geschikt voor wortelwering, bouw en vijvers

De verschillen in dichtheid en structuur bepalen de weerstand, sterkte en toepassingsmogelijkheden van beide materialen.

Kunststof producten bij Kunststof Forte

Kunststof Forte biedt een uitgebreid assortiment polyetheen folies en technische kunststoffen. Ontdek ook onze:

U profiteert bij ons van:

- Fast delivery

- Pay safely

- Personalised service

- Deskundig technisch advies

HDPE folie bestellen

Wilt u HDPE folie op maat bestellen? Kies eenvoudig de gewenste afmetingen in onze webshop en plaats direct een bestelling.

Voor advies of een maatwerkofferte kunt u contact opnemen via

info@kunststofforte.nl or

+31 (0) 622 340 847.