Description

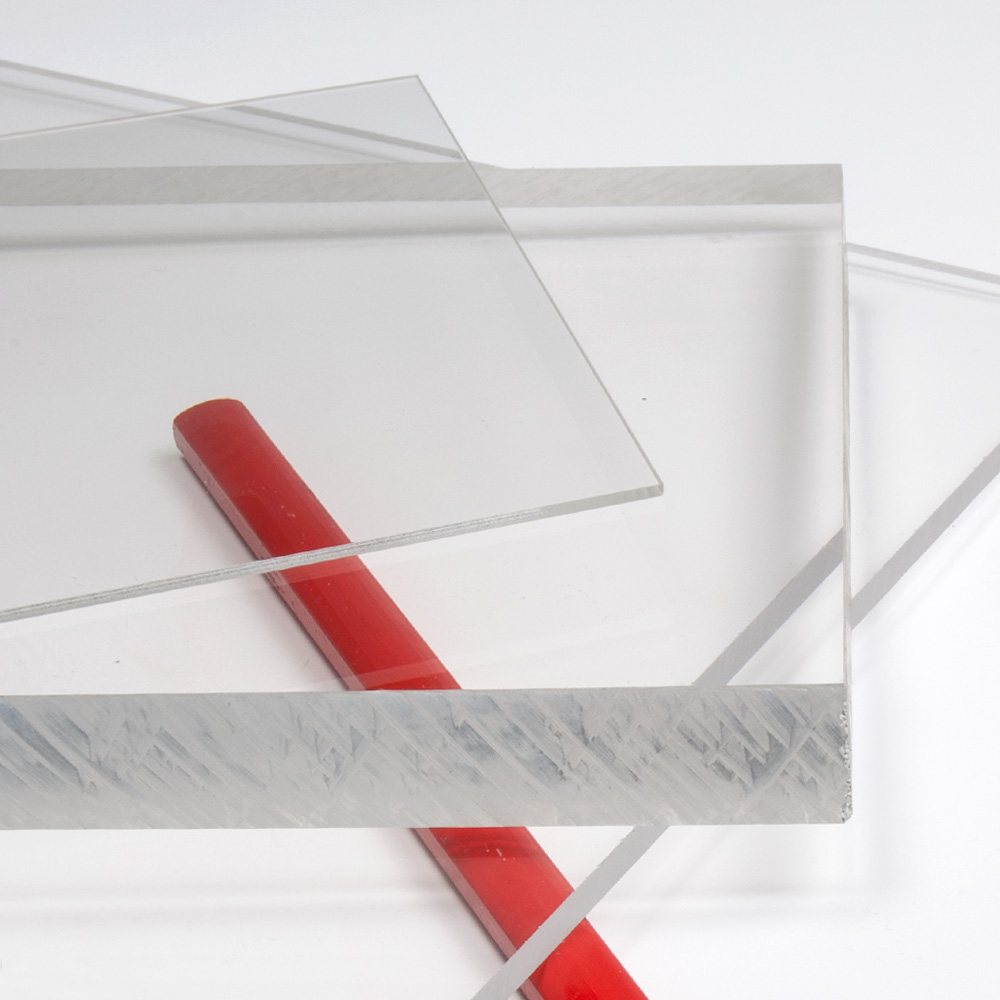

Ordering clear acrylic sheet from Plastic Forte

Why choose a sheet of Acrylic sheet from Plastic Forte? The benefits at a glance:

- Fast delivery

- Pay safely

- Personalised service

- Wide online range

- We are happy to provide you with expert advice

View the range, choose the length and width of your choice and place an order. Do you have a question about the products in our range? Feel free to contact form for more information or request a offer to. We will be happy to help you.

Types of Acrylic

There are two types of acrylic sheets extruded and cast plates. The difference between the two is in the manufacturing process. Extruded sheets are rolled to get them to the right thickness. This reduces the price and for this reason extruded acrylic is also known as cheap and cast as the highest quality.

The difference: cast and extruded acrylic

Acrylic is produced in two different ways, it can be Cast (GS) and extruded (XT). Each method produces its own material properties. In principle, both versions can be processed very well, but each behaves differently during laser processing. It is therefore useful to have a basic understanding of acrylic in order to choose the right acrylic for your application.

Cast acrylic (GS)

Cast acrylic is cast as a liquid mass between two sheets of glass. The result is a homogeneous and tension-free material with equal mechanical properties in directions x and y. However, because of this manufacturing process, the thickness tolerance is significantly higher and is about ±15%. This is the height that must be adhered to for applications with pitch joints. The manufacturing process for cast acrylic is more expensive and therefore cast acrylic also costs more than extruded acrylic. Acrylic laser cutting creates burr-free cuts on both sides. Laser engraving also produces better results than extruded acrylic, namely a perfectly white engraved image results.

Extruded acrylic (XT)

Extruded acrylic is produced by an extrusion process that forces an acrylic mass through a nozzle of the desired thickness. This manufacturing process gives the extruded acrylic different mechanical properties in the x and y directions. In addition, it has a lower thickness tolerance of ± 5% and is therefore very suitable for applications with connectors. When extruded acrylic is cut with a laser cutting machine, it creates a flame-polished cutting edge that is less sharp on one side. Extruded acrylic is cheaper to produce and is therefore also cheaper as a series production. As a rule requires extruded acrylic less laser power than for cast acrylic in the same sheet thickness. Laser engraving on extruded acrylic sheet is not recommended because the result is only matt grey.

Advantages over glass

- Stronger than glass

- Less weight

- Easy to edit

- Sustainable

Electrical properties of clear acrylic sheet

The moisture absorption makes the material less suitable for insulation purposes. The high electrical surface resistance (10.15 Ohm) has the disadvantage that the boards are often highly statically charged.

Food and chemical resistance

Most inorganic substances do not affect Acrylate. The material is non-toxic and may therefore come into contact with food without restriction.

Characteristic features and applications

- Excellent weather resistance

- Very high brightness, more transparent than glass

- 30 times stronger than glass

- Low specific gravity (1.2)

- Good wear resistance

- Particularly suitable for foodstuffs

- High impact and fracture resistance compared to glass

- Optimal surface smoothness

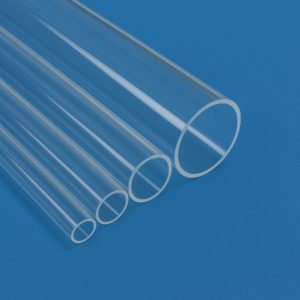

- Excellent for use as balcony panels, stair panels, windshields, illuminated advertising, facade signs, awnings, display cases, boat windows, noise barriers, front glazing, displays, roof domes, lighting fixtures, nameplates, artefacts, furniture and decorative materials.

Order an Acrylic plate clear

Are you convinced of the advantages offered by an Acrylic sheet clear? Choose the length and width of your choice and place an order! Would you first like a offer Tailor-made or request more information? Of course you can. For more information, please feel free to contact form with us.

We can be reached by telephone, e-mail and via the contact form. Call us at +31 (0) 622 340 847 or send an e-mail to info@kunststofforte.nl. Our expert staff will be happy to advise you.