Description

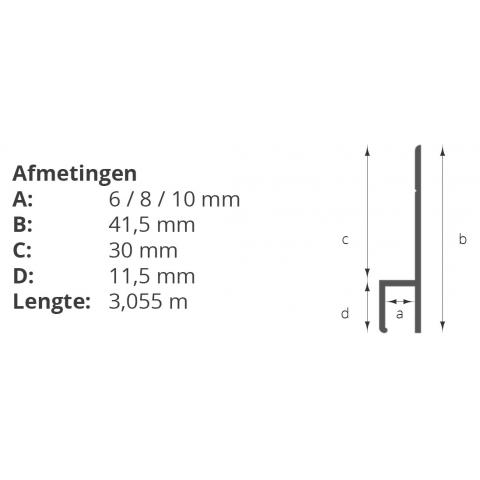

The chair profile (see drawing) is ideal for making horizontal seams watertight because of its high back. EPDM jointing tape must be used on the vertical battens so that the meeting of the vertical battens and the horizontal chair profile is also watertight and the wooden sub-frame is optimally protected against moisture. The chair profile is fixed by sliding it onto the lower board and clamping the back with the board mounted above it.

The profiles are of high quality and are used in facade and interior construction. As standard, these profiles are supplied in lengths of 3.055 metres with a natural anodised surface treatment of 15 Mu. Our supplier can deliver these specific profiles in any NCS, Sikkens or Ral design colour on a project basis. Powder-coated profiles are produced with the Qualicoat® quality label in the standard Ral colours. There is also a choice of various gloss grades of 78% (gloss) or 58% (matt). Furthermore, the material thickness of at least 1.1 mm guarantees a (minimal) risk of buckling of the profiles at free span.

Material properties

- Aluminium EN AW 6060 T60 - AIMgSiO.5

- Available in anodised or qualicoat powder-coated finish

- Gloss levels available: 70° (e.g. - HPL) or 30° (e.g. - fibre cement)

- Profile length: 3.05 m.

Processing instructions

- Respect the processing instructions of the manufacturer of the panels used.

- Fix the back side of the profile between the support structure and the gable panel.

- Provide sufficient space between 2 contiguous profiles so that any expansion of profiles

by temperature fluctuations can be absorbed.

Maintenance

- In case of any contamination caused by environmental or climatic influences (e.g. saw dust during façade construction, soot deposits, escape rust in

coastal areas,...) the profiles can be cleaned with water or a mild soap solution and a soft sponge.

- When using a soapy solution, rinse the facade with water after cleaning.

- The use of solvents or solvents for cleaning is not permitted.

Reviews

There are no reviews yet.