Applications of HMPE Sheets in the Shipping Industry

HMPE (High Molecular Polyethylene) sheets are a popular choice in the marine industry because of their durability, abrasion resistance, and resistance to water and chemicals. From plain bearings to protection of hull and running surfaces, this versatile plastic offers numerous benefits in demanding marine environments. In this blog, we discuss the main marine applications of HMPE sheets and why this material is preferred over other options.

1. Slide bearings and sliding surfaces for ship components

In marine applications, HMPE sheets are often used as plain bearings and sliding surfaces for moving parts, such as hatches, sliding doors and loading mechanisms. HMPE's low coefficient of friction makes it ideal for applications where smooth and quiet movement of parts is required. Moreover, HMPE's wear resistance ensures that the material lasts for a long time, even in continuous use in harsh conditions.

2. Hull and jetty protection

HMPE sheets are excellent as a protective material for ship hulls and jetties. Due to its high impact resistance, HMPE protects the hull from damage when in contact with quays and other objects. Jetties are often fitted with HMPE fenders that absorb impacts and reduce wear and tear on both ships and jetties, contributing to lower maintenance costs and a longer life of both.

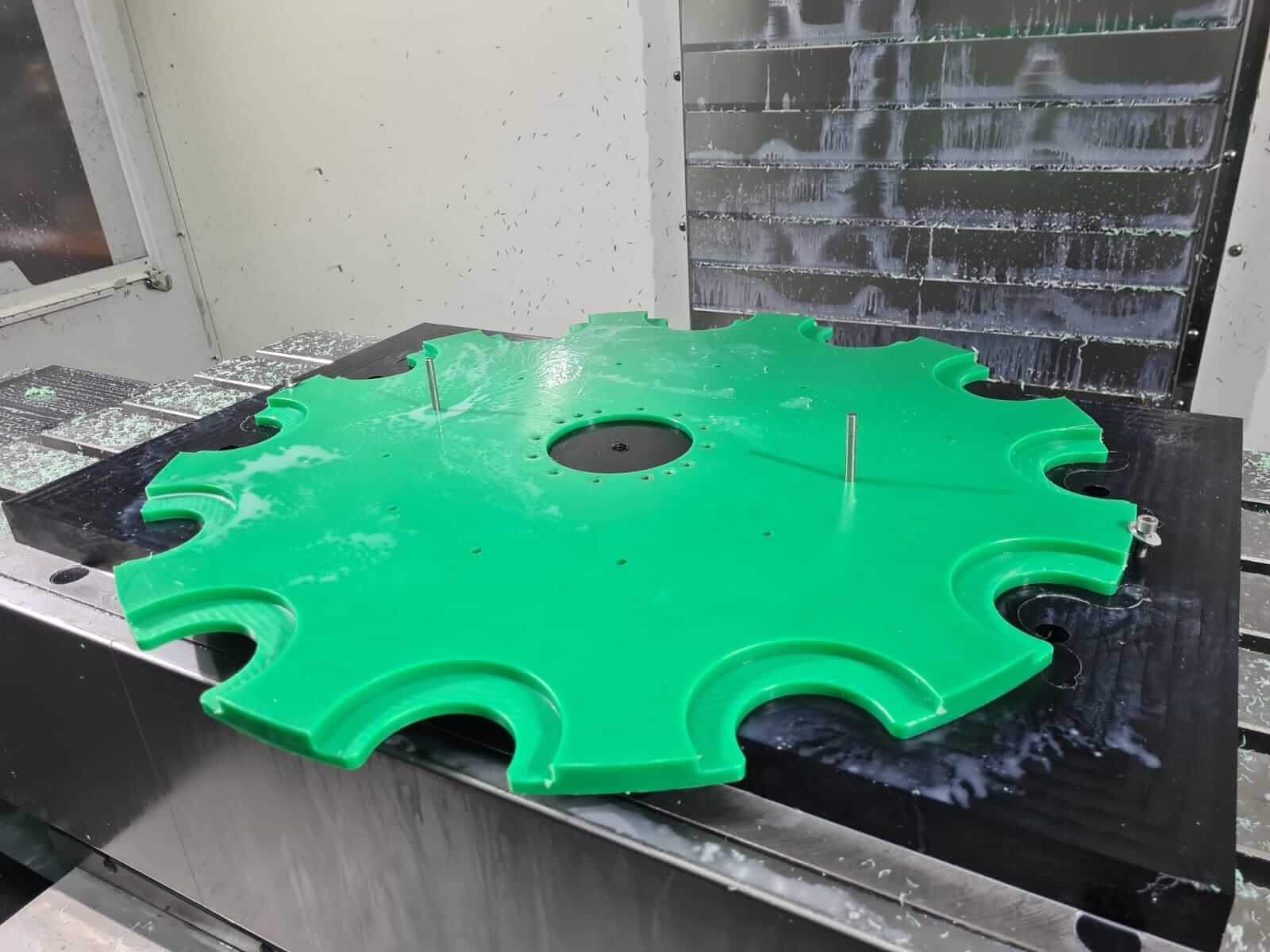

3. Guidance systems and rails

Many ships use HMPE sheets in guidance systems and rails, for example for anchor chains or cargo transport. HMPE has the advantages of a smooth surface and low friction, which reduces the friction of heavy loads. This helps to reduce stress on mechanical systems and ensures that loads can be moved safely and easily.

4. Low-friction cladding for decks

Another popular application is the installation of HMPE sheets as low-friction linings on decks and cargo areas. This prevents cargo from getting stuck or damaged due to excessive friction with the deck. HMPE sheets are also easy to clean and maintain, contributing to hygiene and safety on board.

5. Shock absorption and noise reduction

In marine applications, HMPE sheets can be used to dampen shock and noise. By placing HMPE under heavy equipment, the impact on the ship is reduced, which helps extend the life of ship components. In addition, the damping of noise vibrations creates a more pleasant working and living environment on ships.

6. Corrosion and chemical resistance

Marine applications require materials that are resistant to water, salt and chemical exposure. HMPE is resistant to corrosion and has excellent chemical resistance, making it a reliable choice for exposure to aggressive marine environments. This makes HMPE ideal for components in continuous contact with seawater and other corrosive substances.

Conclusion: HMPE, A Valuable Material in the Shipping Industry

The versatility of HMPE sheets offers the marine industry many benefits, from abrasion and water resistance to low friction and impact resistance. This durable material minimises maintenance costs and improves on-board safety and efficiency, making it a worthwhile investment for any marine application.

Whether for hull protection, guidance systems or shock absorption, HMPE offers reliable solutions designed to last in the challenging conditions of shipping.