What are amorphous and crystalline substances?

What exactly are amorphous and crystalline substances? These amorphous and crystalline substances play a very important role in plastics. For a non-natural or chemically savvy person, this can be quite a complex theory. After all, what do these substances entail? And what is their connection to plastics? Below, we provide you with more information on these specific substances.

The difference between amorphous and crystalline substances

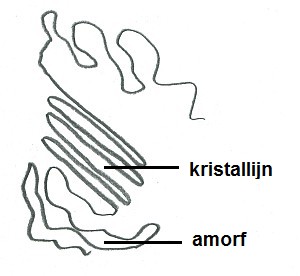

"Amorphous" also refers to amorphous plastic. Crystalline, on the other hand, refers to a specific structure of a plastic at the molecular level. The major difference between amorphous and crystalline substances lies in the way their molecules lie next to and through each other at the molecular level. In the case of amorphous substances, the molecular chains are in fact intertwined like 'spaghetti' and without a specific shape or arrangement. Unlike amorphous substances, in crystalline substances the molecules lie in a fixed and ordered structure. In semi-crystalline substances, the molecules consist of 'islands' connected by ordered molecules.

Different types of plastic

Typically, amorphous plastics are (semi-)transparent. You can think of acrylate and polycarbonate. But also PVC and polystyrene are transparent without the use of dyes. Furthermore, pure crystalline substances are not common, while semi-crystalline substances are common. Think of polyolefins such as polyethylene and polypropylene. These plastics are composed of carbon and hydrogen.

Crystalline plastics become amorphous when heated

The moment a crystalline or semi-crystalline is heated, the molecular structure changes as soon as the substance leaves the glass phase. During the glass phase, the substance is still hard and stable. The substance then enters the rubber phase. As soon as HDPE, PP or PVDF is welded, the molecular structure temporarily changes from semi-crystalline to amorphous. This can be seen very well during the welding of HDPE, PP natural or PVDF. In fact, it is possible to see through the teaching material.

Once the material starts to cool, it turns milky white again. Depending on the quality and the cooling rate, a certain amount of crystals are formed again, which gives this plastic its good properties. To make a good welded joint, it is therefore important that the plastic cools down slowly, so that the molecules lie next to each other again. Cooling too quickly results in degradation. The original PE100 now has the properties of PE80 or less.

Want more information on plastic?

Would you like to receive more information on these amorphous and crystalline plastics? Feel free to call +31 (0) 622 340 847 or send an e-mail to info@kunststofforte.nl. You can also visit our contact form use.